The Challenge:

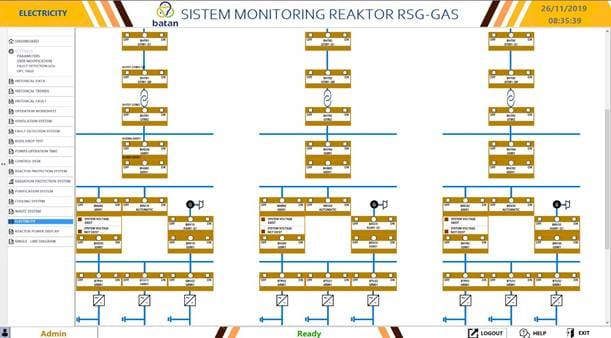

Developing a high-accuracy fault and condition monitoring system for a 30 MW main nuclear research reactor operated by BATAN. The system must capture synchronized data from over 1000 input points with precision timing, integrate with existing systems, and provide intuitive visualization and reporting for technical users and stakeholders.

The Solution:

Using CompactRIO with Real-Time (RT) and FPGA modules, a LabVIEW-based monitoring platform was developed to acquire and process data from more than 1000 channels. The system achieves 10 μs timing accuracy through GPS-based synchronization, enabling coordinated fault detection and performance monitoring across the reactor system. An integrated web-based dashboard allows live remote access to status and conditions, while automated report generation supports data archival and client transparency.

Nuclear reactor systems demand strict operational integrity, precise fault localization, and long-term performance tracking. For this project, Haliatech implemented a custom architecture based on NI’s embedded hardware, ensuring modularity, speed, and synchronization capabilities.

To fulfill this, the system includes:

- NI CompactRIO platform with Real-Time Controller and FPGA-based signal processing

- GPS timing synchronization to align high-speed signal sampling across subsystems

- Over 1000 digital and analog input channels, monitored and logged continuously

- LabVIEW-based interface for real-time visualization and automated reporting

- Web server deployment for online access by BATAN engineers and stakeholders

Key Features:

- High-Speed Data Acquisition – More than 1000 sensor channels monitored with 10 μs precision

- GPS-Synchronized Monitoring – Ensures time-aligned fault detection across all subsystems

- Integrated Visualization – Real-time interface deployed to local clients and over web

- Automated Reporting – Scheduled and event-based reports for operational insights

- Modular Architecture – Built on scalable CompactRIO platform for future expansion

Real-World Implementation:

- Location: 30 MW PRSG Reactor operated by BATAN

- Data Scope: Covers reactor control systems, environmental sensors, mechanical subsystem faults, and operational status

- Operation: System runs 24/7 with fallback redundancy and is integrated into the main reactor diagnostic infrastructure

- Report Access: Accessible via internal LAN and secured web access for authorized BATAN personnel

Benefits:

- Precision Diagnostics: Pinpoints abnormal conditions down to microsecond-level accuracy

- Remote Monitoring: Enables engineers to access and analyze reactor data without being on-site

- Interoperability: Synchronized with other monitoring systems within the reactor complex

- Scalable Framework: Supports additional signal inputs for future subsystems

- Regulatory Support: Assists in compliance reporting and traceability for safety inspections

Referensi:

BATAN – Badan Tenaga Nuklir Nasional

LabVIEW for Measurement and Control